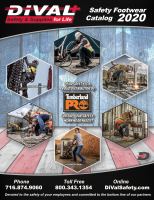

Shoe Technology 101

There are many factors that go into making a

comfortable safety toe shoe. Material, construction,

cushioning and support should all be considered.

In order to be sure that your next safety toe shoe for

work is exactly what you need, it’s important to be

informed about the various technologies that go into

how a safety toe shoe is made.

ASTM Testing

ASTM F2413 - is the official standard for safety footwear in the United States.

At DiVal Safety our goal is to ensure that all of our offerings meet or exceed

industry accepted safety standards. In the United States, the current applicable stan-

dard for protective footwear is referred to as ASTM F2413-11 Standard Specification

for Performance Requirements for Protective (Safety) Toe Cap Footwear. It defines

the minimum requirements for the design, performance, testing, and classification of

safety toe footwear. ASTM F2412-11 defines the procedures used to test protective

toe footwear to the various safety classifications. All of our safety toe footwear meets

or exceeds the ASTM requirements for the type of footwear designated. As a leading

supplier in the safety shoe industry, DiVal Safety continues to update styles, safety

characteristics and features as customers and industry requirements change.

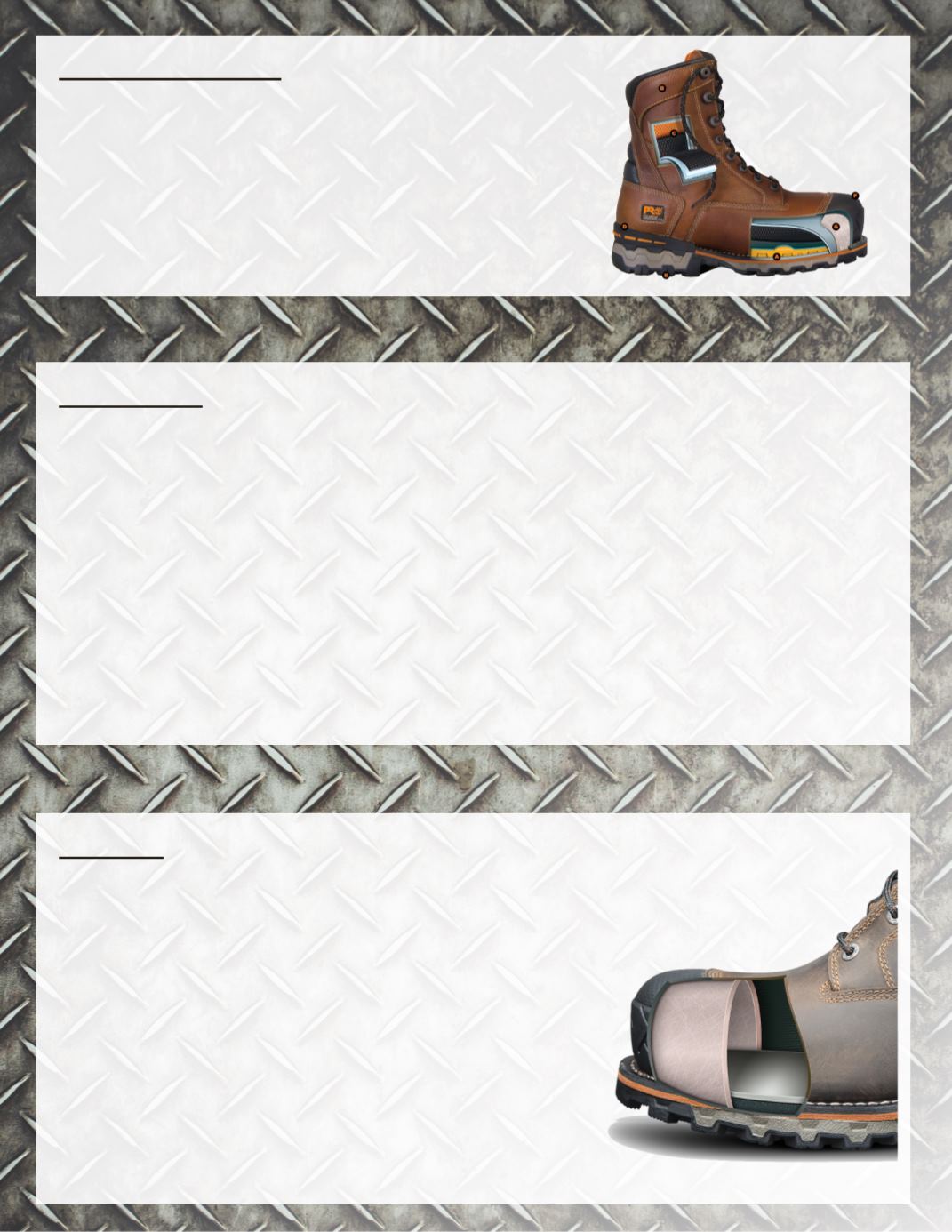

Toe Types

Steel Toe

- Non-corrosive toe caps used in footwear to

provide protection for the toe area. Steel toes meet or

exceed the ASTM F2413 standard for protective footwear.

Composite Toe

- A toe cap made from a non-ferrous

elastomeric material, which is light weight and will not

conduct heat, cold or electricity. Composite toes meet or

exceed the ASTM F2413 standard for protective footwear.

Alloy Toe

- Made of lightweight materials like aluminum

and titanium, but they’re as strong as steel. Alloy toes

meet or exceed the ASTM F2413 standard for protective

footwear.